An inspired approach to quality steel melting and casting production

We began MedSteel with one focus: to build a company that can compete with large production companies while operating with the flexibility and customer-focus of a small, family-run business. We call it small business values with a big business approach.

Today, 75 percent of our business comes from a core group of legacy clients: a testament to our commitment to building strong, long-term working relationships.

We value respect, trust, transparency and the willingness to innovate. We hire people who share and demonstrate these values.

At Med Steel we are helping to build a greener future by producing steel from scrap which is derived from two main sources – scrap steel left over at the end of the manufacturing process and steel which has been formed into products which have no further use – it is all collected and recycled, and this can be done on a never-ending basis.

Guaranteed technologically advanced steel products

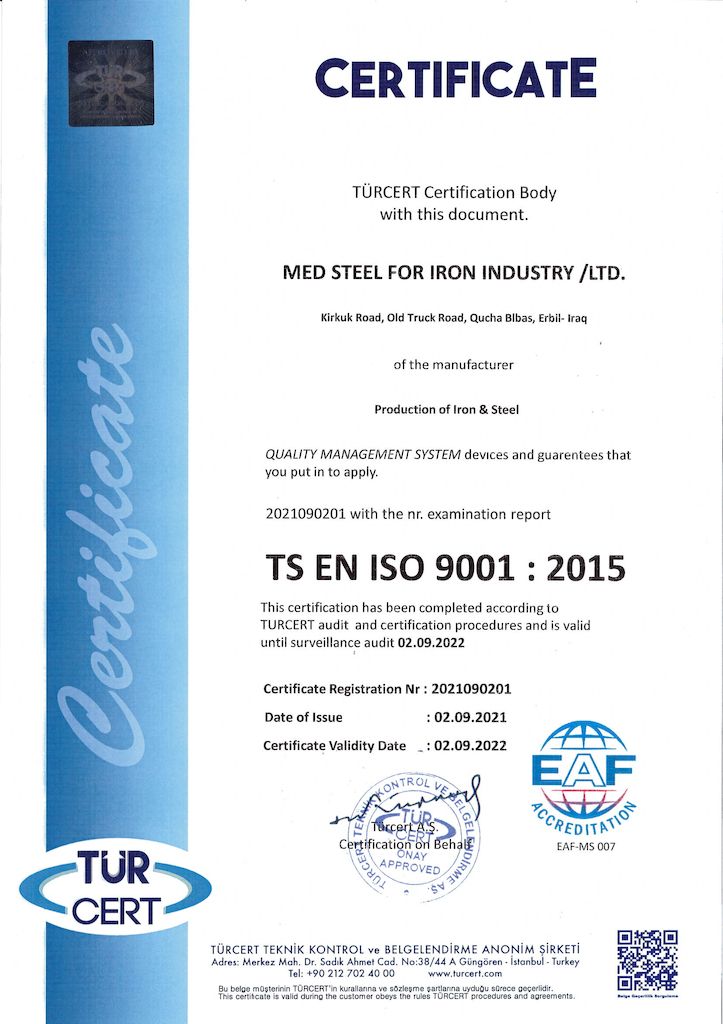

For a clear entrepreneurial choice at MED STEEL, “Total Quality” is not an abstract concept, but a set of operational protocols that direct every stage of the internal organization, the production process and the relationship with our customers. The set of procedural rules, certified with ISO 9001 and ISO 45001 by TURCERT is constantly updated and supervised. The Quality System of MED STEEL is the perfect mechanism for offering our customers a certified and tangible quality.

We project manage the entire design and production process

At Med Steel, sustainability is at the core of our production processes. Steel is produced from iron which is one of the most abundant elements on the planet, and once steel has been produced it is 100% recyclable. It can be re-used time after time on an endless basis without any loss of quality.

Steel is an essential material for society’s needs both today and for the future. It is used everywhere – in housing, transport, agriculture, water supplies, your refrigerator and washing machine, surgical scalpels, ships, your mobile phone, bath taps – the list is endless.

Steel is very much connected to economic growth and prosperity, and emerging nations need steel to build roads, railways, bridges, fencing, water supplies, factories, machinery, sanitation, and more. Figures worldwide show that there are 2.7 tonnes of steel in use for every person on the planet.

The steel that we produce

The steel that we produce

is manufactured from scrap, and it requires relatively low amounts of energy to produce when compared with other materials. Lightweight steel such as that used in buildings and automobiles helps reduce our carbon footprint by saving energy and resources. The steel industry overall has engaged in reducing environmental pollution considerably over the last 50 years, so that today, when we produce one tonne of steel at Med Steel, we are using 40% less energy than was used in the 1960’s.

Steel is essential to the industries

Steel is essential to the industries

and technologies that will drive a greener future. For example, it is used in the production of wind turbines, and it is estimated that by 2050 wind turbines could produce one quarter of the world’s electricity supply if the present growth rate continues. Indeed, with the rapid expansion in the manufacture of electric vehicles, we will need ever more electricity production to charge the batteries.

This will require the development

This will require the development

of a further 100,000 offshore wind turbines and 1 million onshore ones. It is also calculated that over a 20-year period a 3MW wind turbine will produce more than 80 times the energy required to build and maintain it. When a wind turbine comes to the end of its’ life, the steel will simply be recycled once more.

Because the life of steel

Because the life of steel

can be endless as long as it is recycled, every tonne of steel that is produced is a permanent resource for society. At Med Steel we are helping to build a greener future by producing steel from scrap which is derived from two main sources – scrap steel left over at the end of the manufacturing process and steel which has been formed into products which have no further use, such as steel food cans, aerosols, paint cans, old car bodies – it is all collected and recycled, and this can be done on a never-ending basis.

1037

Completed Projects

5798

Qualified Engineers

747+

Work Facilities

30+

Worldwide Branches

Let’s talk about your project

When you hire us for steel production services, you know you’re getting highly qualified professionals who have the expertise and experience to make sure your project is done properly and functions.